Sphere lab technical info

Introduction

The Sphere setup is a sound boot with about 130 speakers arranged in a sphere. In the middle of the sphere is a chair where a person (the subject) can sit, so that his/her head is exactly in the centre of the sphere. The subject can be presented with stimuli in the form of sounds or led flashes. The headmovements of the subject can be tracked. The subject can also respond to stimuli by pressing a button. The experiments are controlled by a computer and electronics from outside the boot.

History:

- 2014: build of the original system

- 2016: the TDT sound system was extended to 4 channels

- 2018: all original Visaton speakers where replaced by Minx12 speakers

- 2018: Remmel head tracking system replaced by Femto

Sound booth

Description

The sound booth is an accoustically isolated room with sound absorbing materials on all walls and the floor. The dimensions are about four meters deep and three meters wide. A 2.8m diameter sphere build of metal tubes holds about 116 small passive speakers and 14 large active speakers. The small speakers also contain 5mm two color LEDs. In the centre of the sphere there is a chair for a subject. The chair is placed in a way that the head of the subject is right in centre of the sphere. Large coils are embedded in the walls of the sound booth. The coils make a cube of about 3mx3mx3m. These coils are used for head movement detection. A metal cabinet contains PLC equipment for controlling the LEDs as well as a patch panel for the small speakers. The large speakers are connected with XLR cables to a large reel. An infrared camera is installed in the booth. The experimenter has a monitor from which he/she can see the inside of the booth. The camera looks down on the back of the subject.

Accoustics

<todo>

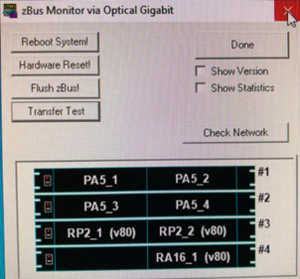

Computer

A windows computer with MATLAB, RPvdsEx and zBUSmon. The computer has an optical interface card (PO5e) for communication with the Tucker Davis equipment via the Optibit optical bus (FO5) at the back of the rack. The working of the optical bus can be monitored by the program zBUSmon program from TDT. This program has also some control functions for the optical bus. It shows all the connected zBus chassis and the TDT devices that are installed in each chassis. It also shows the version number of the installed firmware on the devices.

Electronics rack

The upper half of the electronics rack contains 10 TDT Zbus devices chassis, each containing two TDT series 3 devices. The lower half contains the Field coil amplifier and the Femto LockinAmplifier as part of the head tracking electronics.

The following table shows all the zBus chassis from top to bottom, with the installed devices.

| Chassis | Front left | Front right | Back |

|---|---|---|---|

| Zbus | MS2 Monitor speaker | <empty> | |

| Zbus | PA5 Attenuator | PA5 Attenuator | F05 optibit bus #1 |

| Zbus | PA5 Attenuator | PA5 Attenuator | F05 optibit bus #2 |

| Zbus | SA1 Speaker amplifier | SA1 Speaker amplifier | |

| Zbus | RP2.1 Sound processor | RP2.1 Sound processor | F05 optibit bus #3 |

| Zbus | PM2R Multiplexer | PM2R Multiplexer | |

| Zbus | PM2R Multiplexer | PM2R Multiplexer | |

| Zbus | PM2R Multiplexer | PM2R Multiplexer | |

| Zbus | PM2R Multiplexer | PM2R Multiplexer | |

| Zbus | RA16ba base station | RA8GA2 multi DAC | F05 optibit bus #4 |

The next list shows all other electronics in the lower half of the rack from top to bottom.

- PP16 Patch panel for Medusa Base Station (2x)

- Digital event recorder

- Junction box panel (connects to junction box in sound boot)

- Trigger distribution panel

- Femto Lockin amplifiers

- Tektronics Oscilloscope

- Field coil amplifier

- Rack main power switch

- Patch panel for XLR output to Tannoy speakers

Optical Interface

Four of the Zbus chassis in the rack have an optical interface (F05) at the back. These optical interfaces are connected in a loop with the P05e interface at the back of the computer. PO5e optibit bus F05 optibit bus (4x) Transfer rate: read 1.5 Mbit/s, write 1.0 Mbit/s N.B. The optical bus is not 100% stable. Once in a while it hangs up the program. Issue #196 on GitLab.

Sound system

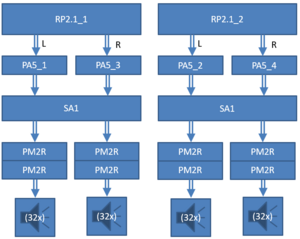

The sound system consists of two programmable DSP’s (TDT RP2.1’s) with each two DAC’s. An RP2.1 generates a sound signal that travels via a programmable attenuator (TDT PA5), a stereo amplifier (TDT SA1) and a multiplexer (TDT PM2R) to a patch panel inside the PLC cabinet in the boot and from there to a speaker. The multiplexing system consists of two sets of four multiplexers (TDT PM2relay). Each multiplexer has 16 channels. Only one channels per multiplexer can be opened at a time. The total number of channels is 128. Each RP2.1 controls four multiplexers. Since each RP2.1 has 2 DAC outputs, each output is connected to two multiplexers. It is therefore possible to play up to 4 different sounds at once over different speaker. Parts

- TDT RP2.1 (2x)

- TDT PA5 (4x)

- TDT SA1 (2x)

- TDT PM2relay Multiplexers (8x)

- Flat cables from RP2.1 to PM2relays (2x)

- Dsub25 cables from PM2relays to PLC cabinet in the boot (8x)

- Patch panel inside the PLC cabinet

- Speakers (116x)

Minx12 speaker system

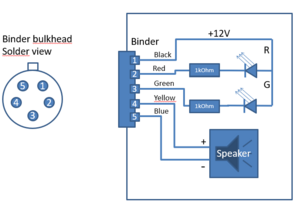

The Minx12 speakers are connected via 5 lead wires with a 5 pole binder connector at each end. Two leads are used for the speakers, three leads are used for the LED’s.

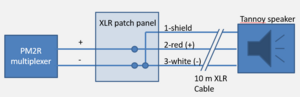

Tannoy speaker system

There are 14 Tannoy speakers in the horizontal plane. These are active speakers with their own amplifier. The speakers are used when lower frequencies (50Hz-150Hz) are important. Due to hiss problems, the original block transformers have been replaced by toroidal transformers. The Tannoy speakers are connected with XLR cables to a special patch panel at the bottom of the electronics rack, and inside the boot to a panel on a XLR cable reel. Since the output of the TDT soundsystem does not have a balanced output, the shield of the XLR cables are connected to the minus leads. The Tannoy speakers can be connected to a multiplexer using a special flat cable that connects to the back of the XLR patch panel.

| Channel | Pin MUX | Pin PP | MUX | XLR |

|---|---|---|---|---|

| GND | 1 | 1 | ALL 32 | GND |

| A10 | 20 | 15 | 1-2 | 1 |

| A11 | 8 | 3 | 1-2 | 2 |

| A12 | 21 | 16 | 1-2 | 3 |

| A13 | 9 | 4 | 1-2 | 4 |

| A14 | 22 | 17 | 1-2 | 5 |

| A10 | 20 | 5 | 1-4 | 6 |

| A11 | 8 | 18 | 1-4 | 7 |

| A12 | 21 | 6 | 1-4 | 8 |

| A13 | 9 | 19 | 1-4 | 9 |

| A14 | 22 | 7 | 1-4 | 10 |

| A15 | 10 | 20 | 1-4 | 11 |

| A12 | 21 | 8 | 2-4 | 12 |

| A13 | 9 | 21 | 2-4 | 13 |

| A14 | 22 | 9 | 2-4 | 14 |

| X | X | X | X | 15 |

| X | X | X | X | 16 |

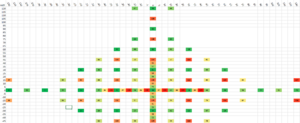

LED system

The LED system consists of a cabinet inside the sound boot with a Panasonic FP2 series PLC system (programmable logic controller). The PLC can independently switch 256 channels. The channels connect to a two color LEDs (red and green) that are mounted on the speaker. The PLC cabinet has two test buttons that can light all LEDs at once. The PLC system consists of a PLC with several IO units and is can be programmed by via a special USB cable.

Parts

- Trigger from Medusa base station

- PLC cabinet (houses PLC system)

- FP2 PLC system from Panasonic

- Break-out panel with 5 pole Binder connectors (128x)

- Binder cables (120x)

- LED mounting frames (120x)

- Red/Green LED’s (120x)

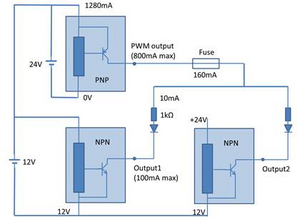

- Trigger converter (5V → 24V) for input trigger

- Trigger converter (24V → 5V) for trigger echo

Specifications Panasonic FP2 series

- FP2C2LJ FP2SH PLC

- 1 ms cycle time when <20.000 steps per cycle (120.000 steps max)

- Measured cycle time 1.35 ms

- FP2Y64TJ output unit (4x)

- 64 channels

- 24V NPN output

- Current 0.3A max

- Response time <0.3 ms

- FP2PXYPJ multi I/O unit

- PNP transistor

- PWM output 30 kHz

- Duty cycle 0-100% in steps of 1%

- Max output 800 mA

- FP2X16D2J input unit

- 16 channels

- Current 8 mA @24V

- Response time <0.2 ms

Specifications Red/Green LEDs

- Bivar 5BC-3-CA-F (Common Anode)

- Red 625nm (FWHM = 25 nm)

- Green 568 nm (FWHM = 30 nm)

- Nominal current 20 mA

- Voltage drop 2.1V

- 45 degree viewing angle

- Series resistor 1kOhm

- Actual current 10 mA @100% PWM

Trigger/Timing system

Description

The task of the trigger/timing system is to distribute trigger signals and record the timing of the triggers. In the standard situation when an experiment starts, the subject has to push a button to start a trial. The button push is registered by an arduino trigger bridge that outputs a trigger to the Medusa Base Station. The Medusa sends triggers to the RP2.1’s, the LED PLC and to the Event Recorder. The Event Recorder timestamps all the triggers and can be read out via ethernet. The arduino trigger bridge has a green LED that indicates that a trigger signal is generated and it has a test button that generates a trigger signal when pushed.

Parts

- Pushbutton

- Arduino trigger bridge

- Patch Panel PP16

- Medusa Base Station (TDT

- Event Recorder

Specification

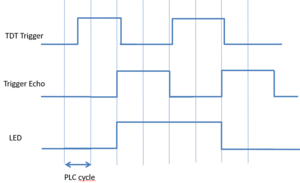

The LED PLC in the LED controller cabinet can be programmed by Matlab. The PLC stores a list of LED configurations. One configuration tells the PLC which LEDs should be on or off. In the standard mode (X = 0) the current configuration is changed to the next configuration by an electrical trigger signal. A stimulus of a single LED consists of two configurations, one with only that LED on, followed by one with all the LEDs off. The timing and the length of the stimulus are controlled by trigger signals sent from the Medusa Base Station. The PLC cycle of 1.35 ms is the limiting factor for the shortness of a LED stimulus. In practice the pulselength can be as short as two or three PLC cycles (2.7 ms or 4.0 ms) in the standard modus (X=0). The number of cycles the stimulus lasts can vary by one cycle. In practice there is always 1.35 ms jitter on top of a 1.35 ms delay for the start (and end) of a LED stimulus (see figure). When more precise knowledge is needed over the timing or length of the stimulus, a timing signal (trigger echo) sent from the PLC can be recorded. The trigger echo signal is lined up with the rising or falling flanks of the LED and can measure the real stimulus with an accuracy down to 40 µs.

When using short stimuli the X parameter can be used to control the exact number of cycles. When X = n the length of the LED stimulus is exactly n PLC cycles.